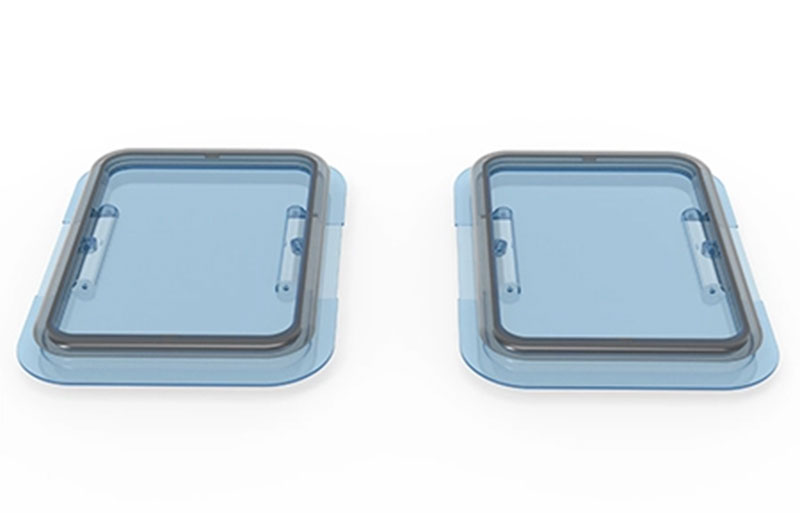

Double Injection Molding Services

Pro Success Group provides two type processes for double injection molding.

One is in a broad sense of double molding includes overmolding with double injection molding by an ordinary molding machine.

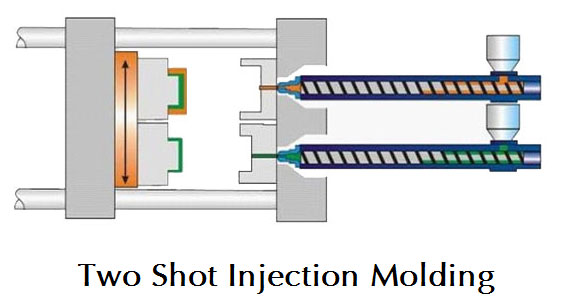

And the other is in a narrow sense, double injection molding refers to using a two-color injection molding machine, two different plastics in the same machine to complete the injection parts. The common is rotary.

What Is Double Injection Molding?

The double injection molding is realized on the double shot injection molding machine. One material is injected into a product, and then on the two-shot machine, it jumps to the mold cavity corresponding to another injection barrel by turning the mold. The part is used as an insert, and another material is injected into it to form an integrated two-material product. The injection molding machine is a dual barrel and dual mold cavity. The injection molding process is to produce products of two materials at the same time, but the products of one cavity will enter the next cavity as inserts. Double shot injection molding technology is also called dual material injection molding technology. It is a technology of mixed injection molding of two plastic materials into plastic products. Its technical connotation is actually to use a mold component to shape the shape and weld the molding work in the mold. Therefore, the fundamental principle is to plasticize two different plastic raw materials, Then the mold is welded and installed to achieve the purpose of two shot injection molding.

Double Injection Molding Parts