Insert Molding Service

Pro Success Group provides custom insert molding services for both low-volume and high-volume production. Using advanced tooling, we seamlessly integrate metal inserts or other components into plastic parts, ensuring enhanced strength and durability. With competitive pricing and a variety of materials to choose from, our insert molding solutions are designed to meet your specific functional needs and budget.

Enhance your products with our insert molding solutions services. We seamlessly integrate metal and plastic components, delivering durable, high-performance parts with precision and efficiency.

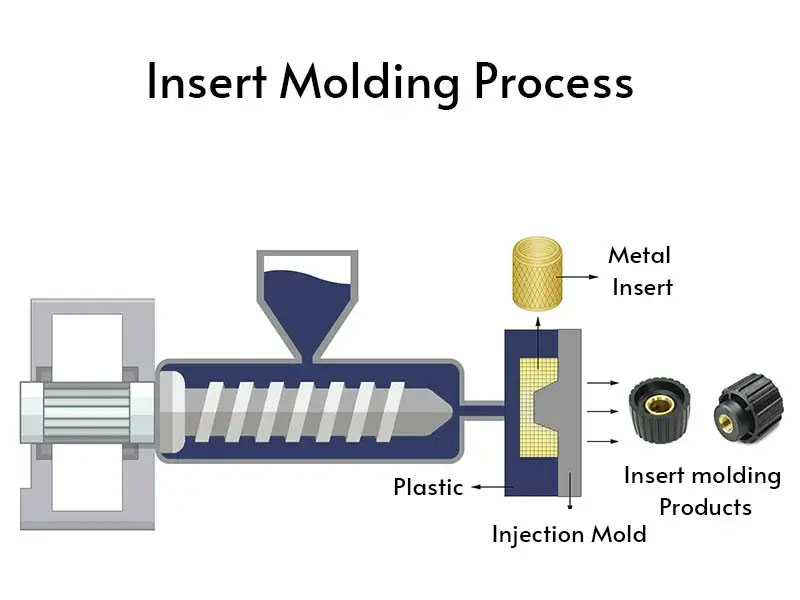

What Is Injection Molding?

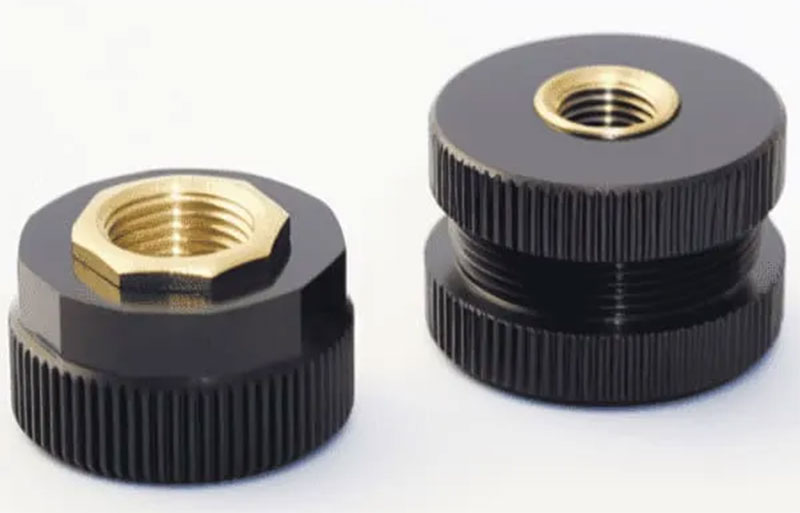

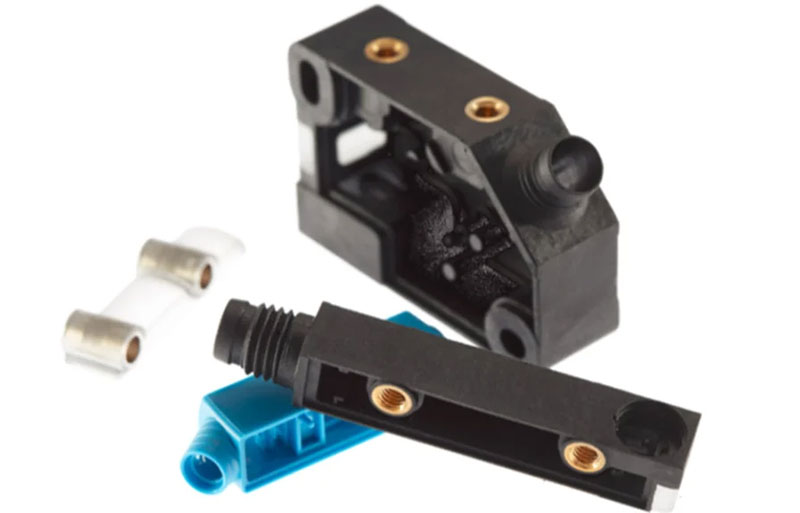

Insert Molding is an injection molding process that works especially well for parts that have threaded holes. It can also help you create better wheels, pulleys, fan blades, and other similar parts. Done correctly, insert molding can help:

- Eliminate assembly: You can make insert molded parts all at once instead of having to do assembly after the fact.

- Reduce costs: Insert molding costs more than standard injection molding, but the costs are usually offset by the fact that you no longer need to do post-assembly.

- Lower the size and weight of the part: A plastic part with a metal insert is generally lighter than an all-metal part.

- Improve reliability: Metal mold inserts will guarantee the function of threads and mitigate wear and tear over the part’s life.

- Improve part strength: Because it’s a “one-shot” process, it can produce stronger parts than overmolding and other processes.

Insert Molding Parts