CNC (Computer Numerical Control) machining is a precision manufacturing technology that uses pre-programmed computer software to control machine tools. The key steps in the CNC machining process include:

1. CAD Design: Creating a 3D model of the product using computer-aided design software.

2.CAM Programming: Converting the CAD model into G-code instructions that the machine can interpret.

3.Machine Setup: Installing appropriate cutting tools, fixtures, and calibrating the workpiece.

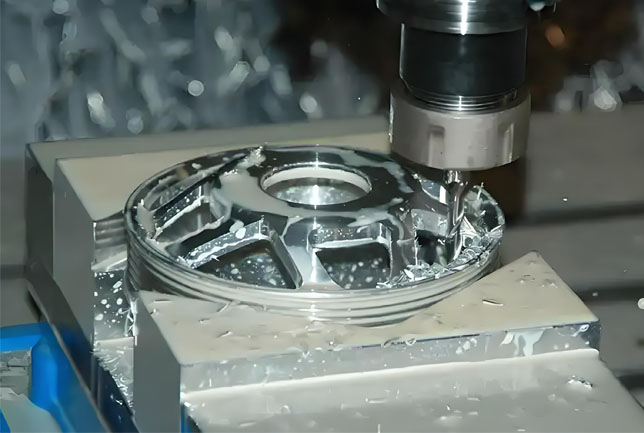

4.Machining Process: The CNC system automatically controls the machine to execute cutting operations according to the program.

5.Quality Inspection: Verifying machining accuracy using measuring instruments.

CNC machining can process various materials, including metals (such as aluminum, steel, and titanium alloys), plastics, and composite materials. The techniques include milling, turning, drilling, boring, tapping, and more.

Advantages of CNC Machining in Production

CNC machining has revolutionized modern manufacturing, offering several key advantages:

1.High Precision and Repeatability:

Achieves tolerances as tight as ±0.001 inches (approx. 0.025 mm) or better.

Ensures consistent quality in mass production.

Reduces human error and improves product yield.

2.High Production Efficiency:

Enables 24/7 automated production.

Faster processing speeds, ideal for high-volume production of complex parts.

Multi-axis CNC machines can complete multiple operations in a single setup, reducing handling time.

3.Exceptional Flexibility:

Easy adaptation to different product requirements by modifying the program.

Quick changeover between production tasks, shortening development cycles.

Suitable for small-batch and customized production.

4.Cost-Effectiveness:

Reduces labor costs in the long run.

Minimizes material waste through optimized cutting paths.

Lowers costs associated with defective parts.

5.Complex Machining Capabilities:

Produces intricate geometries that are difficult or impossible with conventional machines.

5-axis CNC machining enables complex curved surface processing.

Micro-CNC allows for ultra-precise micromachining.

Characteristics of CNC-Machined Products

Products manufactured using CNC technology exhibit the following key characteristics:

1.Superior Surface Finish:

High surface smoothness (up to Ra 0.4 μm or better).

Uniform surface treatment.

Reduces the need for secondary finishing processes like polishing.

2.Strict Dimensional Consistency:

Minimal dimensional variation in mass production.

Ensures interchangeability in assembly.

Particularly suitable for precision industries like aerospace and medical devices.

3.Ability to Produce Complex Structures:

Can machine internal cavities, irregular surfaces, and intricate geometries.

Enables monolithic designs, reducing assembly components.

Achieves shapes that are difficult or impossible with traditional methods.

4.Preservation of Material Properties:

Precise control of cutting parameters minimizes heat-affected zones.

Maintains the original mechanical properties of materials.

Especially important for post-heat-treatment machining.

5.Greater Design Freedom:

Capable of producing almost any conceivable shape.

Supports rapid prototyping.

Facilitates product iteration and optimization.

Applications

CNC machining is widely used in industries such as:

Aerospace: Engine components, airframe structures.

Automotive: Transmission parts, engine blocks.

Medical Devices: Artificial joints, surgical instruments.

Electronics: Smartphone casings, heat sinks.

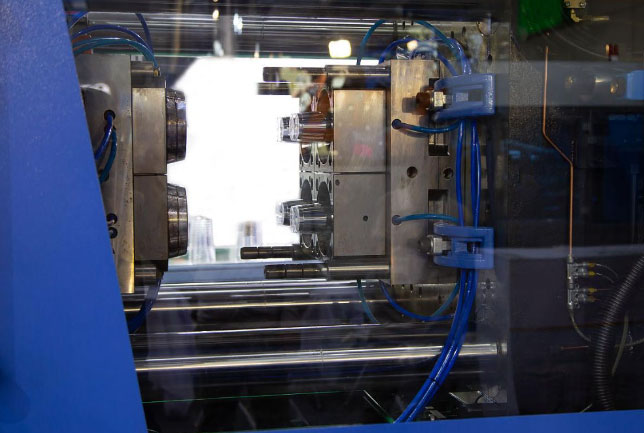

Mold Making: Injection molds, die-casting molds.

Energy Equipment: Turbine blades, oil drilling components.

CNC machining, with its high precision, efficiency, and flexibility, has become a cornerstone of modern manufacturing. It not only enhances product quality and production efficiency but also expands the possibilities of product design. As technology continues to advance, CNC machining will play an even more critical role in the era of smart manufacturing, delivering superior machining solutions across industries. Welcome to contact us to customize your CNC parts.