In today’s era of rapidly advancing digital printing technology, silk-screen printing continues to hold a vital position across industries such as apparel, electronics, and advertising due to its unique technical characteristics and broad applications. As an ancient printing technique, silk-screen printing has not been phased out; instead, its exceptional color performance, material adaptability, and cost efficiency have made it the preferred solution for mass production and high-quality printing.

Core Advantages of Silk-Screen Printing

1. Superior Color Vibrancy and Coverage

Silk-screen printing employs a physical pressing method, with ink layers up to 10 times thicker than those in digital printing. This results in vivid, highly saturated colors, particularly effective for printing light-colored designs on dark materials. For instance, printing a white logo on a black T-shirt requires no pre-treatment—unlike digital printing, which often needs a white underbase. Additionally, silk-screen printing supports specialty inks such as fluorescent, glow-in-the-dark, metallic, and 3D raised effects, unlocking greater creative possibilities.

2. Unmatched Material Compatibility

Unlike digital printing, which is limited to paper or specific fabrics, silk-screen printing can be applied to almost any substrate, including:

– Textiles (T-shirts, caps, tote bags)

– Paper & Packaging (posters, labels, gift boxes)

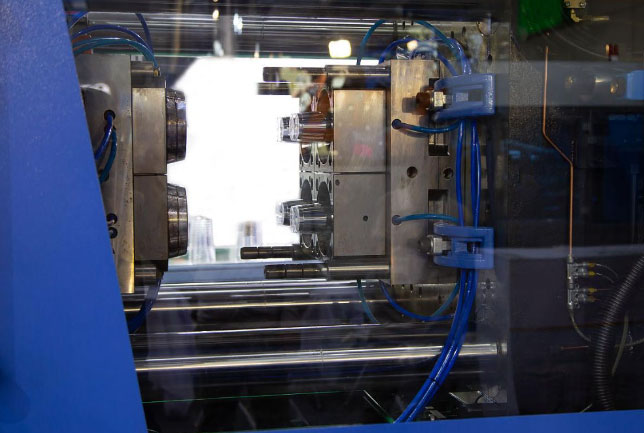

– Plastics & Glass (beverage bottles, acrylic signage)

– Metals & Ceramics (industrial components, commemorative items)

– Wood & Leather (handicrafts, custom furniture)

This versatility makes it ideal for cross-industry production.

3. Exceptional Durability for Outdoor & Industrial Use

Silk-screen printing inks, cured through heat or UV treatment, exhibit strong adhesion and resist frequent washing, abrasion, and UV exposure. This durability makes the technique indispensable for workwear, sports gear, and outdoor signage. For example, military and firefighting uniforms often rely on silk-screen printing for long-lasting identification markings.

4. Cost Efficiency for Mass Production

Although silk-screen printing requires stencil preparation, resulting in higher initial costs, its per-unit expense drops significantly for large orders (e.g., 100+ pieces). For custom T-shirts, bulk pricing can be as low as one-third that of digital printing, making it the go-to choice for brands and promotional campaigns.

Industry Applications

1. Apparel & Textiles

– Fast Fashion: Brands like H&M and Uniqlo use silk-screen printing for select graphic tees to balance cost and quality.

– Sportswear: Nike and Adidas depend on the durability of silk-screen printing for team jerseys and training uniforms.

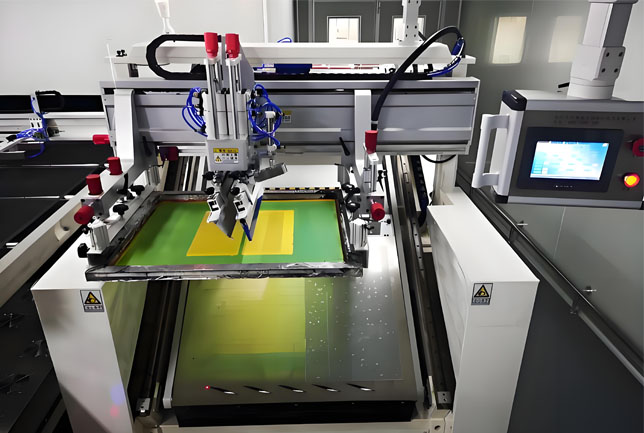

2. Electronics Manufacturing

– PCB Production: Silk-screen printing precisely applies conductive inks, a critical step in electronics manufacturing.

– Control Panels: Buttons and labels on appliances and industrial equipment often use silk-screen printing for clarity and wear resistance.

3. Advertising & Packaging

– Limited-Edition Posters: Artists like Andy Warhol used silk-screen printing to create iconic pop art.

– Premium Packaging: High-end perfume bottles and liquor labels frequently employ silk-screen printing for metallic finishes.

Technology Comparison: Silk-Screen vs. Digital vs. Heat Transfer

| Feature | Silk-Screen | Digital | Heat Transfer |

| Bulk Cost | Lowest | Higher | Moderate |

| Special Effects | Fluorescent, 3D, metallic | Limited | Standard |

Despite the growth of digital printing in small-batch customization, silk-screen printing remains a manufacturing cornerstone due to its cost efficiency, durability, and versatility. With advancements in eco-friendly inks and automated equipment, this traditional process is poised to expand further into premium and sustainable production markets.

For businesses, choosing silk-screen printing means lower costs, extended product lifespans, and broader design possibilities—key reasons for its enduring relevance in the 21st century. If you have the custom need, please get in touch with us.