Brass is a special copper alloy. Brass is an object made from an alloy of copper and zinc. It is named for its yellow color. Brass with 56% to 68% copper has a melting point of 934 to 967 degrees. Brass has good mechanical properties and wear resistance. Due to its unique advantages, it has become an important part of the parts manufacturing industry. Generally used for precision copper parts such as auto parts, medical parts, electrical parts, etc. Brass CNC machining has many advantages over other metal CNC machining processes, which is why the demand is there. This article discusses several benefits of CNC machining with brass.

Several potential advantages of brass CNC machining

The following tips will help you understand why brass CNC machining will never go out of style.

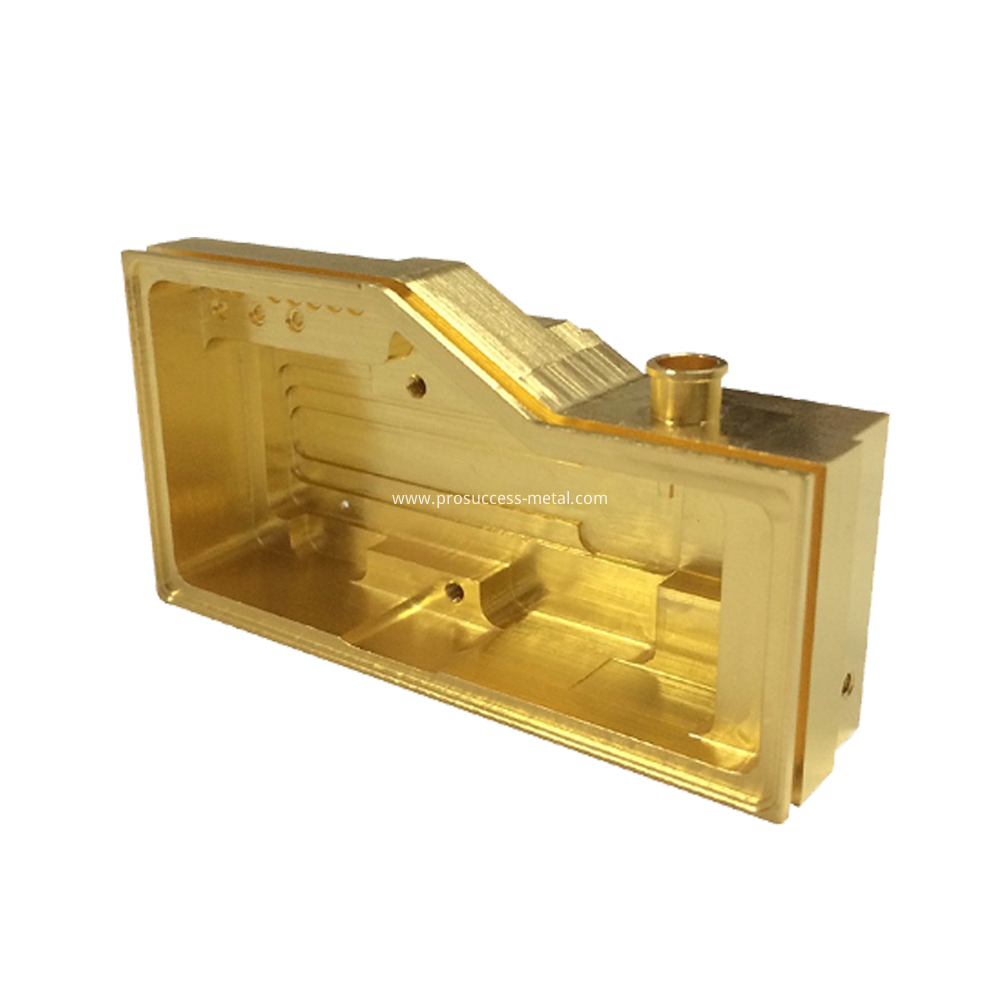

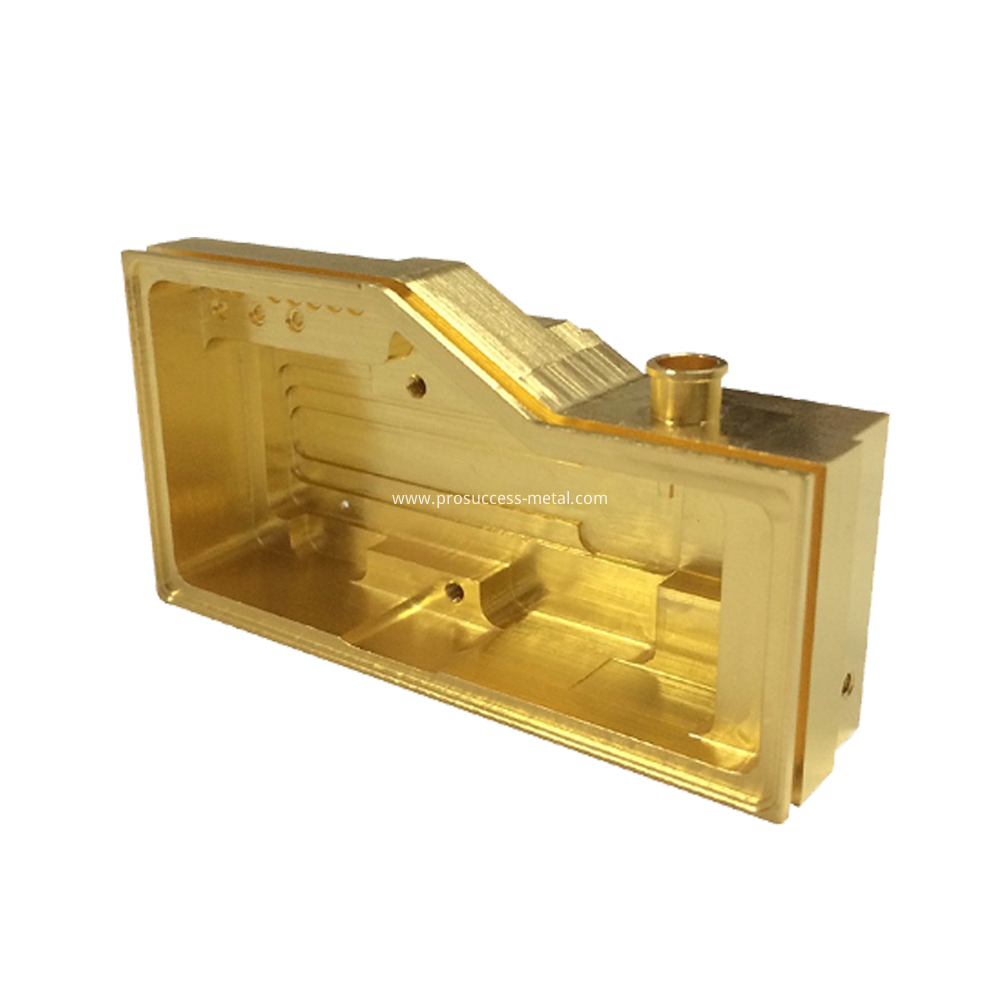

Brass cnc machining precision parts

Brass has excellent machinability, sometimes referred to as 100% machinability. The mechanical properties of this alloy are high strength, high tensile strength and shear resistance. These characteristics contribute to the speed of machining with brass cnc. Research shows that machine shops can and should process material at feeds and speeds (typically 5 to 20 times faster) than current productivity and profitability improvements.

Brass cnc machining precision parts

For example, today`s brass rods are not only easier and faster to machine, but also have no negative impact on tool wear, fast part surface finish or chip formation. With the power and robustness of the latest high-speed machines, the shop can increase the removal rate of brass workpiece material in milling, drilling and turning operations. Also, according to research, alternative materials such as steel and stainless steel lack the competitive high-speed machining advantages that brass brings.

Precision cnc machining and dimensional stability

Known for its dimensional stability, brass is also suitable for manufacturing with tight tolerances. Brass components remain dimensionally stable due to the small deformation coefficient and high impact resistance.

High compatibility of workpiece tools and tools

In brass CNC machining, chip formation is negligible, so tool wear is minimal. Generally speaking, brass rod workpieces are the first choice for CNC machining. These workpieces are highly compatible with various CNC machining tools. Tool durability and frictionless machining increase machining efficiency.

Higher productivity and profits

As a fast and precise machining process, brass CNC machining can improve machining efficiency. Brass is a relatively economical and convenient material, so it is conducive to the capital investment of processing materials. The durability of the tools during this process is high, thus reducing the cost of frequent tool changes. In addition, no post-processing is required for this process. Together these factors lead to higher productivity and profits.

Environmental protection

Brass is a copper alloy that retains the chemical or physical properties of natural copper. However, some properties of this alloy are enhanced. Therefore, the materials in this process are environmentally friendly. Additionally, brass CNC machining does not inject any harmful gases or chemicals into the environment. Brass is also recyclable. Brass' high scrap value enables manufacturers to cover most of the initial raw material costs through scrap buyback programs. The scrap is then processed into chips to produce new brass again and again without losing the material's properties.

Brass cnc machining precision parts

Ease of handling:

Brass is a versatile material that is easy to precision cnc machining. Brass has good ductility and ductility, so brass automotive parts can be obtained in a variety of shapes, sizes and surface finishes.

heat resistance

Brass has high heat resistance, allowing parts to function properly even at high temperatures.

preservative

Corrosion can cause parts to wear out, shortening their useful life. Brass parts are rust resistant due to the corrosion resistance of brass. This means less maintenance for these parts. It can greatly reduce the maintenance cost in the later period.

So far, the benefits of brass CNC machining have been discussed. Now you can be sure to machine these brass precision parts from a company you can trust for a high-quality product. Prosucces-metal is a trusted CNC machining manufacturer. For ten years, it has been serving the medical parts manufacturing, automobile, ship and other industries.